If you are the upkeep manager at a redistribution facility, you undoubtedly appreciate even the well-designed conveyor belts call for repair services to prevent breakdowns and offer them throughout life. Certainly, failures and poor efficiency may make the whole plant grind to a stop, but precisely how could you avoid them?

Conveyor Belt Repair Tips

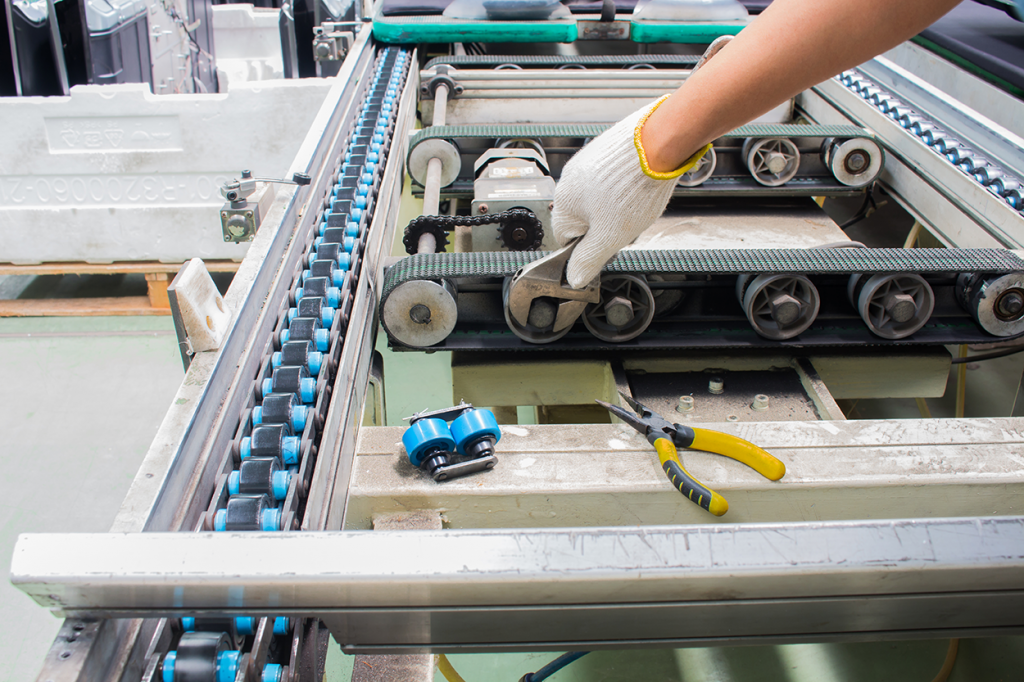

Keep an Extra Conveyor on Site

It is no secret that the dynamic use of conveyor belts at some point leads to wearing and also the requirement for maintenance. An effective upkeep program for the conveyor relies on having replacements, especially for the usual replacement parts. If a minor detail is harmed, be it a nut or area of the belt chain, it might cause manufacturing inefficiencies. Thus, make sure to get components, like bearings and puller plates, and keep them ready for use. This way, you will certainly have the ability to repair unanticipated problems quickly, stay clear of extended downtimes and keep the plant’s efficiency as high as feasible.

Perform Regular Inspections

When the conveyor belt breaks down, the opportunities are that it began establishing issues a few days or months away. This suggests that if you liked examining the straps, the odds are that issues would indeed have been noted before becoming a severe problem. For that reason, it is essential to make the evaluation a daily regimen, focusing on parts and sections that break down frequently.

Implement Preventive Maintenance

If you only take care of concerns with the conveyor belt the moment it breaks down, you would be utilizing a lot of time to repair. Such a strategy is also most likely to enhance downtime and maintenance expenses. Instead, you need to embrace a preventive upkeep model, which needs you to do regular fixings to deal with concerns before they lead to significant malfunctions. Likewise, it is a great suggestion to embrace automation in the center and establish essential indications that reveal when special equipment needs upkeep. For instance, if your central heating boiler begins getting too hot, it would be easy to keep in mind that and have the thermostat be repaired before the whole system grinds to a halt.

Work with Experts

Among the most ignored heroes in commercial centers are the females and men with belts. One of your company’s most significant mistakes is failing to hire experienced professionals or underpaying them. Consider it by doing this, “Would certainly you choose the least expensive medical professional in town?”

An excellent plant specialist will undoubtedly recognize and fix concerns before becoming significant problems. So, beginning by working with highly qualified personnel and training them consistently. It would certainly be best if you likewise motivated the professionals to guarantee they relate to the plant and place even more initiative into enhancing production.

Document all Repairs and Maintenance

This important activity could help you pinpoint components that constantly fail and equip the workers with the crucial understanding to identify trouble indicators. The paperwork can likewise help with quicker diagnosis in emergencies to lessen downtime.

Conclusion

The tips above can help you keep your conveyor belts from leading problems, maximize production, and reduce conveyor belt repair costs. Keep in mind always to purchase the very best belts and components and also have them mounted by expert specialists.