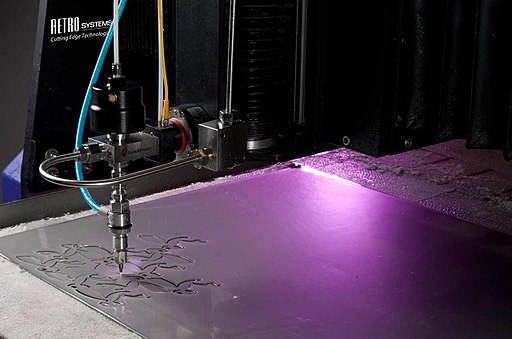

If your profession is in line with engineering or designing, the odds are high that you might have heard for countless number of times how advantageous is the use of waterjet cutting machine over several other profiling methods and what it can deliver to your business interests.

We have heard over and over about waterjet cutting technology and its high precision rate, fast turnaround time or its tough power to cut through almost every imaginable material you can use it for, what we may not have full awareness of will be the different applications in which this cutting-edge technology is suited in.

Industry-Specific Applications

The ability of waterjet cutting machine to seamlessly cut through a wide spectrum of materials, its high level of accuracy and quality of seamless cutting are all factors that makes it among the most preferred profiling method in various industries.

Below is a compilation of these industries that have found that they can take advantage of waterjet cutting technology for their own profiling requirements.

Aerospace

Leading names in the aviation industry have taken good advantage of the waterjet cutting. This process is mostly seen and utilized in cutting the following:

- Engine components

- Body parts

- Interior panels of the cabin spaces

- Military aircraft titanium bodies

- Structural components and custom control panels for special-purpose aircraft.

- Turbine blades trimming

- Seats, struts, aluminum skin, shim stock

- Exotic metals that are utilized in the manufacture of the landing gear.

Automotive

Waterjet cutting is also in high demand in the automotive sector. This is particularly true in the train and car manufacturing business. Below is a compilation of the specific parts by which the water jet technology is put to good use:

- Interior trim for carpet, trunk liners, headliners, etc.

- Body components made from fiberglass

- Insulation

- Specialty brake disks

- Specialty metal gaskets used in old vehicles and automobiles

- Intricate fittings and decorative brackets.

- Custom motorcycle bodies

- Firewall

- Under-hood

- Bumpers

- Truck bed liners

Electronics

Among the primary benefits of waterjet cutting is the contribution it makes in reduction of the costs of production of electrical components. This is a primary concern for most companies so that they will stand a chance of penetrating and competing in today’s highly saturated technology market. The waterjet technology has got the following cutting of parts covered for this industry.

- Cable stripping, or sometimes referred to as insulation coverings

- Circuit boards

- Custom control panels for electrical enclosures

- Custom designed panels for elevator control

- Portable generator components

Medical/Surgical

The ability of waterjet cutting technology to deliver high precision machining for small machine components makes it the method of choice to apply in the surgical and medical sector. The common applications of waterjet cutting in this space include the following.

- Composites,

- Cutting through the components of artificial limbs

- Blanking out surgical paraphernalia and instruments.

- Carbon braces fabrication

- Model shop prototyping

Artwork, Design, and Architectural

There is a manifold of applications for waterjet cutting in the creative sector. This would be ranging from the textile, design, even to architecture. We have here some of the various applications that waterjet cutting is practically used in.

- Architectural and artistic murals and designs.

- Artwork using metal as its base, this includes a theme park, museum artwork, special lighting.

- Window systems

- Architectural trim components

- Signage letters in aluminum, plastic, brass, marble, and glass.

Food Manufacturing

In the food manufacturing business, there are 2 applications you will find waterjet cutting technology is used in.

It is utilized in fabricating the actual equipment for food processing or it is used as an important element in the process of food production because it does not generate heat. Besides, it is also completely sterile in nature.

Examples of which will include:

- Food production

Frozen food, production of biscuits and cakes, vegetable slicing.

- Food processing equipment

Food packaging and handling equipment, beverage manufacturing equipment, food guard/enclosures, food processing lines, etc.

It is quite impossible to come up with an exhaustive list of the many different applications for water jet cutting. But, given the few examples shown above, they should be more than enough to give you a good idea how extensive are the capabilities of this technology is in as far as material cutting is concerned.